In the June 2007 edition of Railway Modeller was an article on the Bodmin 0 gauge layout of Ray Green using Infra Red train control. Could this be the answer to my prayers? I began researching and a couple of days later saw me on a visit to Steve Leyland at MicroMotive in Clay Cross Derbyshire, to have a look at their IR system 'Red Arrow' http://www.a1micromotive.co.uk/Red%20Arrow%20home.html

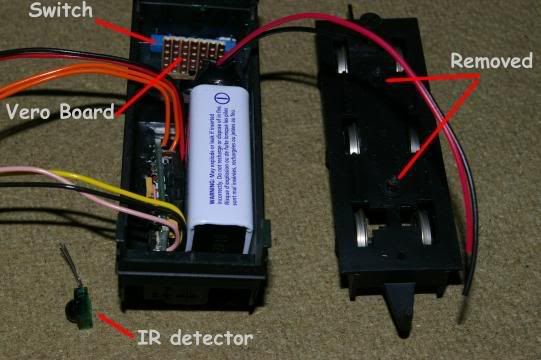

Needless to say I returned home with an IR system - a controller and a bag of bits capable of fitting out two loco's

THE CONTROLLER &

THE BITS - Which are left to right:-

The module

Reedswitch

IR detector

Limit resistors

(nb You have supply the battery and connector)

After reading the instructions several times I assembled a test rig to try out the bits before attempting to fit them in a loco.

TEST RIG

I only used a small 3volt motor for the test but everything worked great.

Now came the bit I really hated, butchering a loco and tender - it always seems like sacrilege to deliberately damage something you've probably treasured for years. So I called it surgery and made every effort not to to more damage than was absolutely necessary.

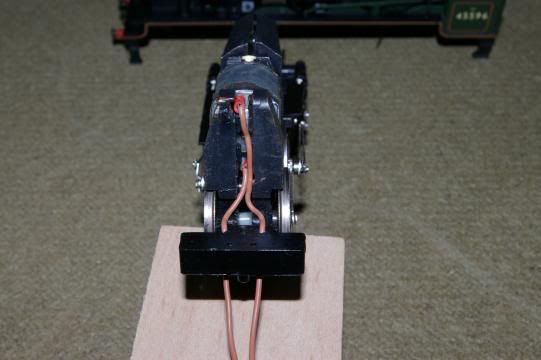

This pic shows the module on the back of a Bachmann Jubilee tender - just to give an impression of size.

MODULE ON TENDER

The first job I did (I realised later that this should have been left until later because if I couldn't get the module and battery in the tender then this bit would have been pointless, still - lesson learned) was to remove the power pickups from the loco, as I was fitting a new power source.

No easy ride for me then. Stripping the Jubilee, I soon realised there were no actual pickups, but this one used a split metal chassis with two springs pressing onto the motor contacts. MMmm.

SPLIT CHASSIS

The two little springs fitted in the holes shown. They simply pressed against the motor contacts on the can.

I decided to remove the springs (saving them for later), isolate the contacts and take two leads out the rear of the loco to the tender.

ISOLATED CONTACTS.

The rubber isolators shown didn't work as they were too bulky to allow the sides of the chassis to be assembled correctly. I eventually changed them for two small pieces of insulation stripped from mains cable.

MOTOR FEEDS FITTED.

I re-assembled the loco and simply hooked up a 9v battery to the two leads. First thing I noticed (this was a new standard PP3 battery) was an apparent loss of power and the engine didn't seem to go as fast as before. I stripped it down and re-assembled it again - same result, so I placed the loco on track and bingo it went as fast as before, so it must be the fact it is powered by 9v instead of 12v.

This may be a problem when it hauls decent length trains but, as still had plenty to do, would have to be tested later.

Now the butchery, sorry surgery, on the tender.

Inside the tender of the loco are three metal plates used as ballast. My first go was to remove the middle one and replace it with a suitably trimmed piece of plasticard which I split across the middle, put them back in, creating a slot through which I could thread a cable tie to secure everything piggy back style.

CABLE TIE SLOT.

I stacked the battery and module onto the plates. A bit like this:-

PIGGY BACK (nb the little thing sticking up at the coupling end is veroboard - see later)

In addition to these bits, I still had to fit the detector, a reed switch, a limit resistor, a bridge rectifier plus connections etc - would I have room?

The switch was no problem. The one supplied is a proximity reed switch supplied with a magnet. In its normal state the contacts are closed - allowing a circuit. Put the magnet onto it and the contacts break thus breaking the circuit. A little test showed the magnet was powerful enough to work through the tender sides.

REED SWITCH

Using double sided tape the switch was stuck to the underside rear of the tender.

All I have to do to turn off the power is to rest the magnet on top of the tender as shown above.

I then had to manufacture an assembly containing a bridge rectifier and a limit resistor (which I think is 720ohm_. This is not absolutely neccessary but means dismantling the tender each time the battery goes flat. What I wanted was to be able to charge the battery by standing the loco on live track.

So a short while later I had made this bit of kit (on the veroboard shown above) and fitted all the parts onto the tender chassis and tried to put the top on................Absolutely no way would they all go in.

Think and re-think and re-re-think.

I then remembered a classic bit of advice my old Dad gave me when I was repairing a motorbike or something:-

"If thy canna fit it reet, turn t'arse about face 'n try agin"

Interpretation - If you can't get something to fit correctly, turn it upside down and try again.

Exactly Dad, thanks. I was trying to put everything on the chassis and hoping the top would fit. I took everything off and placed it in the now upside down body shell, which seemed much easier really.

Trying it again I was till struggling for space, so out came the ballast plates and their securing supports - just about do it if I place the detector in the top but on one side of centre.

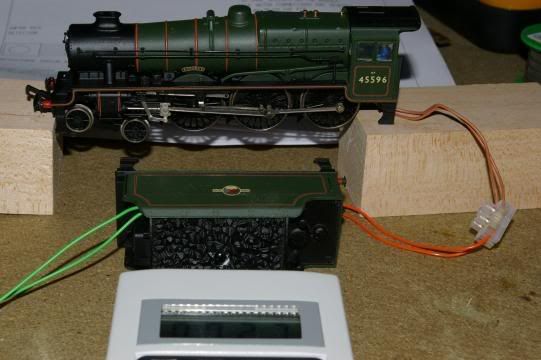

PACKED IN THE TENDER SHELL.

This view shows the detector epoxied into the roof of the tender but placed to one side to allow maximum room for the battery.

INTERNAL VIEW

and another view from the topside - I have still to tidy this up as the epoxy seeped through the gap a little.

TOPSIDE.

HURRAH. Everything fitted - but would it work?

WORKING TEST

This shot shows the engine, yet to be connected properly to the tender, under test. WORKED FIRST TIME. The wheels are actually turning quickly but the camera has frozen the action.

(nb. Ignore the green wires which will eventually be used as power pickups for the battery re-charge system).

One or two problems but I got there. I'm quite satisfied actually as, other than wiring up a few LED circuits,I've absolutely no experience or knowledge of electronics.

Problems detected and yet to be resolved:-

1) Apparent lack of power (9v versus 12v) will it pull a train?.

2) The system allows programming of 99 locos. Factory default sets all chips at 27 but I can't re-programme this one. It won't move off 27.

3) Reading the instructions I think I need a transistor heatsink. I've a rough idea of what it is and what it does but, how big is it, where do I fit it and where do I get it from.

4) Still to fit power pickups for battery re-charging. Should this be via tender wheels (easier) or should I strap them on the loco split chassis (better pickup)?

5) The jubilee has a moulded coal load forming the roof of the shell. What to do about those that have little or no coal?

6) Will the continual charge/discharge ruin the battery.

7) Once finally connected, the engine and tender are paired for life with the wires going from one to the other. Can I find a miniature or micro connector small enough to do the job?

Some things I have learned;-

It won't fit in tank engnes.

It won't fit in locos with tender drive motors.

Well that's as far as I've gone so far. I'll keep you updated of my progress.

Mike