This is by no means the only way but will hopefully point the reader in the right direction.

For this guide I am going to describe the technique I used for my DC control panel using specific items and materials but it should be emphasised that there are numerous products, methods and end results available to the modeller. I am not affiliated with any of the products used. D:

Items I have used are;

Point Motors: Gaugemaster Seep PM1 [From SignalBox]

Panel Switches: Mini Toggle Switch (on)off(on) Spdt [from the Forum Shop]

LEDS: 5mm 12v [from the Forum Shop]

LED Holders: 5mm LED Panel Clip [from the Forum Shop, 3mm Pictured]

Wire: 7/0.2mm [sourced locally]

Terminal Blocks: 3amp [sourced locally]

Wood for the panel itself

Solder, screws, paint, masking/insulating tapes and other various materials to build

I will describe the process I used to build the control panel itself first. I built it as an distinct unit that could be worked on away from the layout in the comfort and good light of my kitchen. When complete it could then be wired up internallywhich will I will describe in Part 2 of the article.

Part 3 will describe the external wiring.

PART 1: Building The Panel

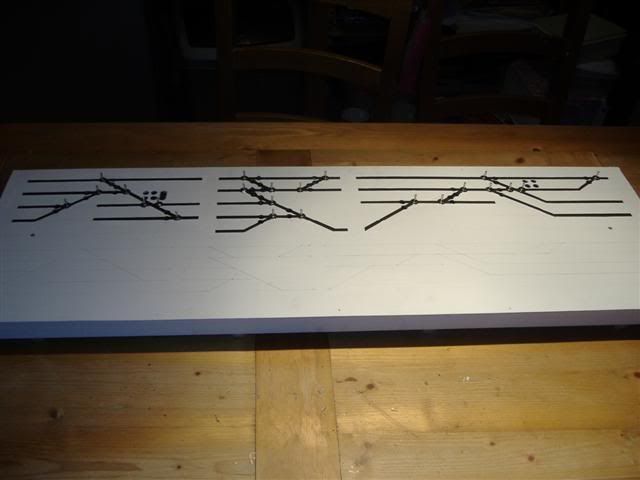

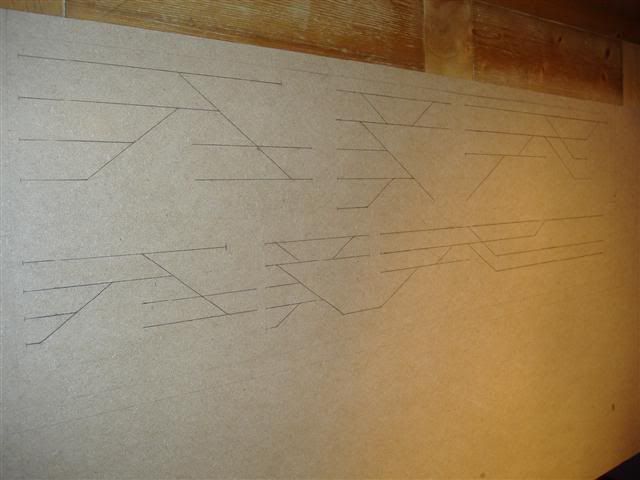

First I drew out a schematic for the track i was looking to 'control'. First on paper then transferred to the front piece of MDF for the panel [please note the top half only is for point control, the bottom half is for insulating sections]

This was then painted white, and track was painted on. The method is used was maksing tape and painting, it would be esaier to use some sort of pen, however due to the size of my lines i decided to paint.

Construction of the panel was as per a baseboard, 1 1/2"x 1 1/2" bracing wood screwed to the 3mm MDF front sheet.

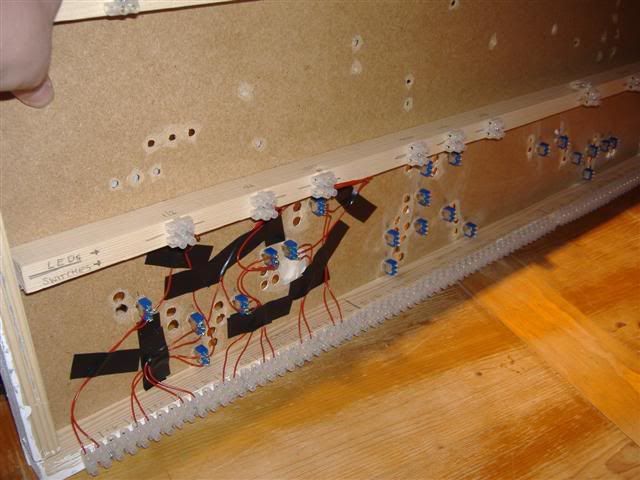

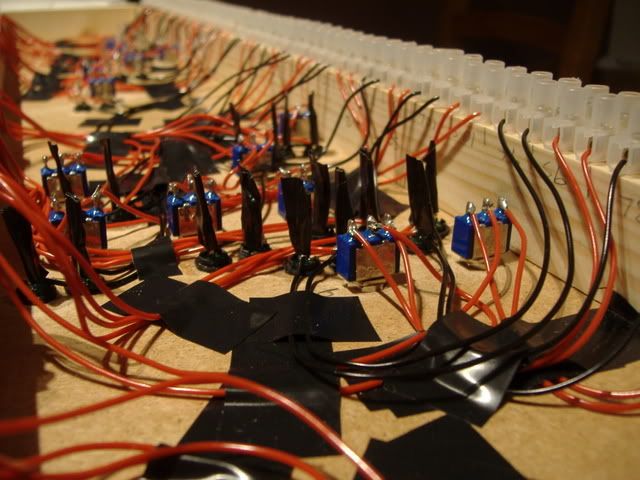

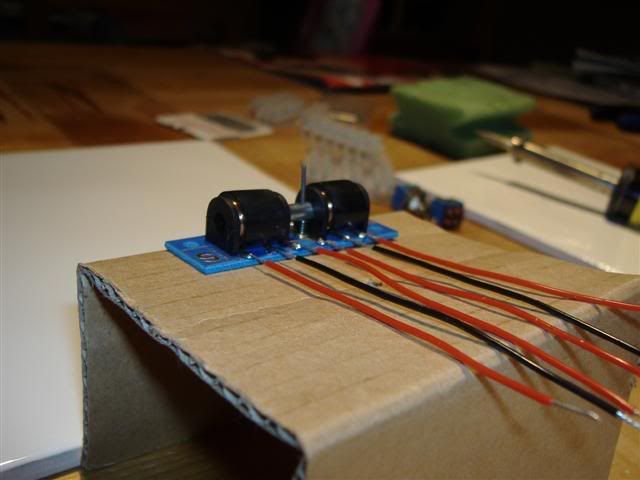

I had all the parts I needed to build this and although wiring point motors up comes in later, there is one job that can be done at this stage: soldering wires to the motors. As well this I wired these wires to chock blocks, to make wiring up the motors under basebaords easier. I made a small jig to hold them in a good position to work on.

After painting and marking out track i drilled the holes for switches and LEDS [I may have drilled before painting actually, I can't remember!]

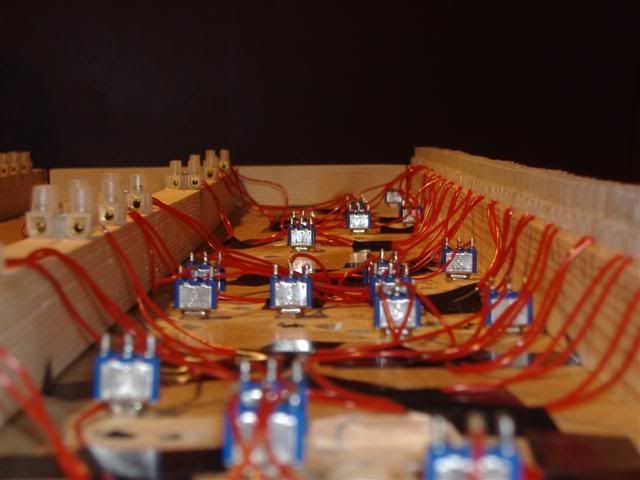

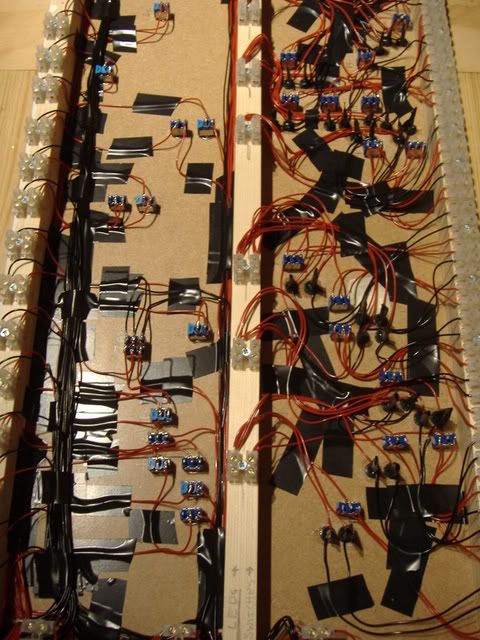

Then i began screwing in the switches and glueing in the LEDS.. I did not find a reliable glue for this.. I used Superglue and some LEDS are loose.

Starting to look right.

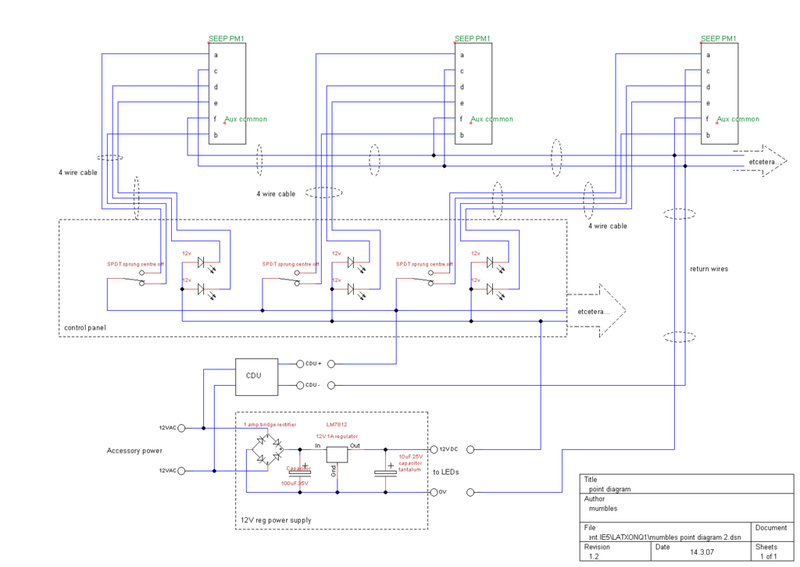

When you have done all this prep work you can start to think about wiring it all up which will follow in Part 2 when i have found a decent version of the wiring diagram and re uploaded it.

Cheers

Michael