Brassmasters Duchess test build

Re: Brassmasters Duchess test build

Wouldn't I just love to spend some time with you Jim.

Watching and being given a talk through as you progress.

I know you have the tools, but without the ability to use

them they just become more 'stuff' in a box.

Geoff T.

Watching and being given a talk through as you progress.

I know you have the tools, but without the ability to use

them they just become more 'stuff' in a box.

Geoff T.

Remember ... I know nothing about railways.

http://www.newrailwaymodellers.co.uk/Fo ... 22&t=32187 and Another on http://www.newrailwaymodellers.co.uk/Fo ... &sk=t&sd=a

http://www.newrailwaymodellers.co.uk/Fo ... 22&t=32187 and Another on http://www.newrailwaymodellers.co.uk/Fo ... &sk=t&sd=a

Re: Brassmasters Duchess test build

After a longer gap than would have liked attention had returned to my Duchess build.

Starting with the lower firebox and damper operating rod.

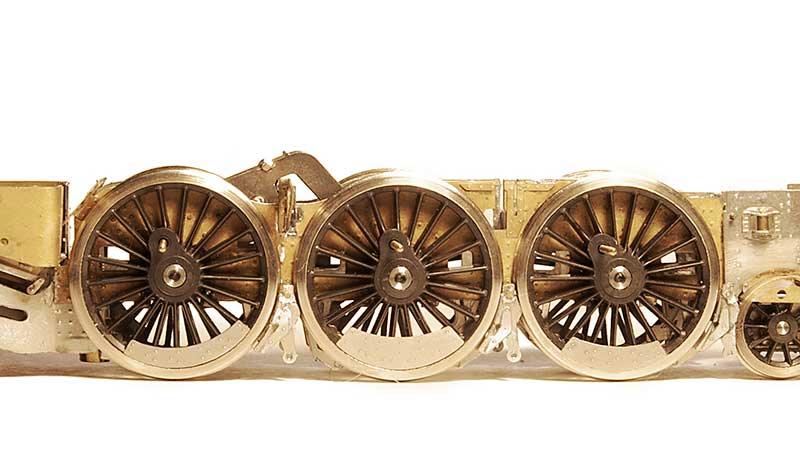

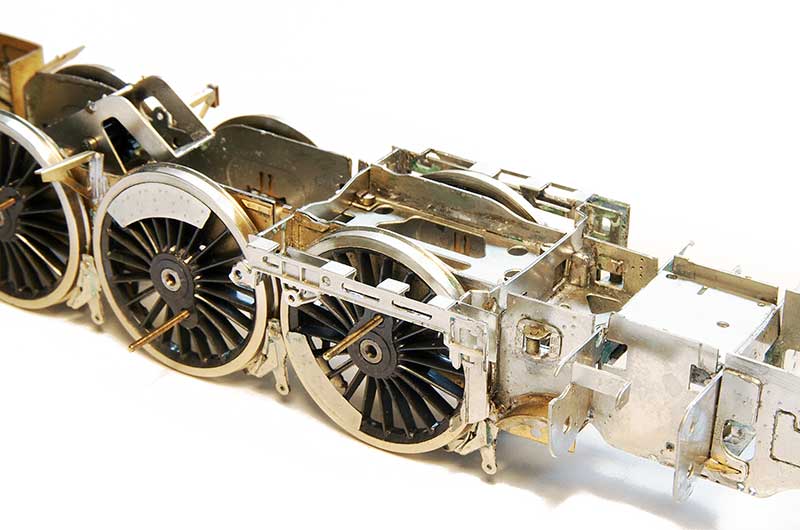

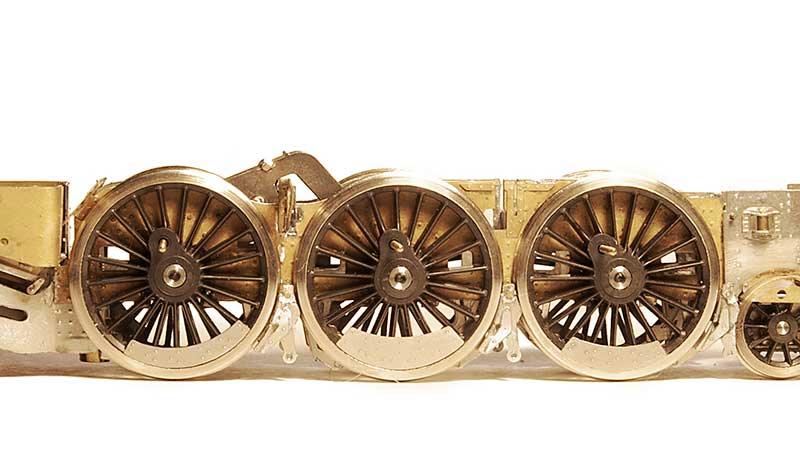

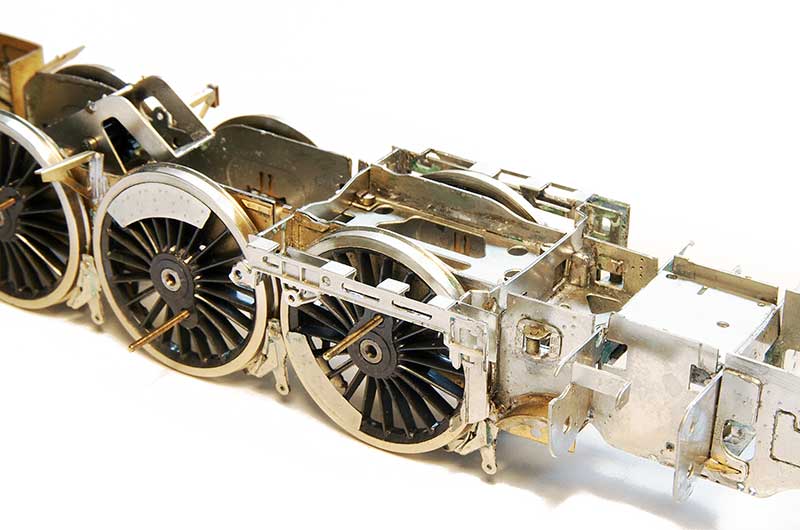

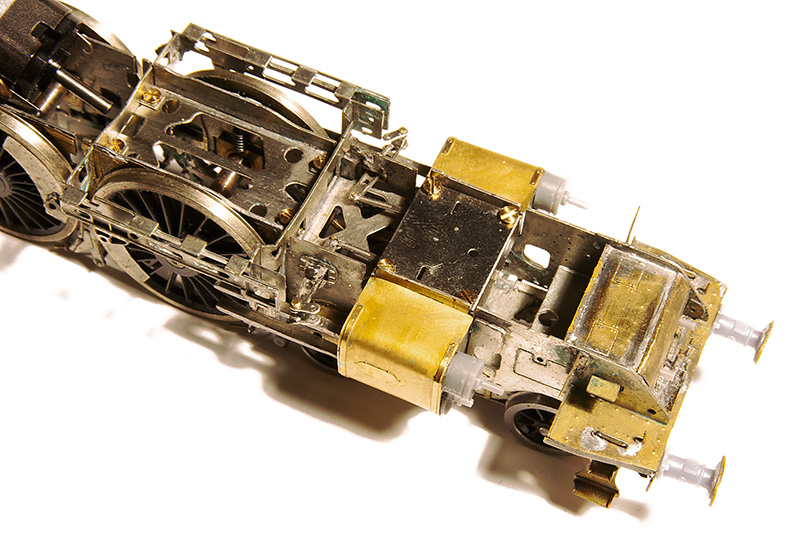

Next up the brakes. As can be seen clearance is kind of on the minimal side. Theres no springs fitted yet either so the chassis sill sit a little higher than is seen here.

The motion brackets. Again theres not a lot of clearance between the bracket and the leading driving wheel.

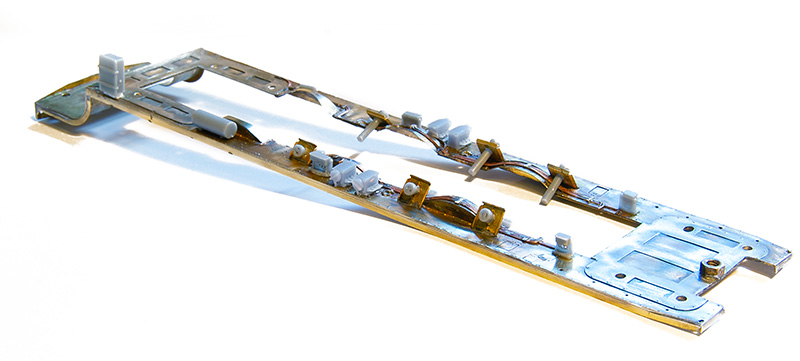

The chassis so far.

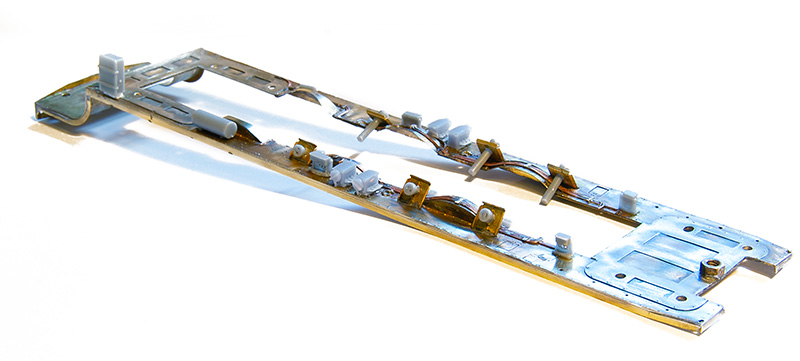

Moving on the next stage is the footplate, seen here in its assembly jig.

Starting with the lower firebox and damper operating rod.

Next up the brakes. As can be seen clearance is kind of on the minimal side. Theres no springs fitted yet either so the chassis sill sit a little higher than is seen here.

The motion brackets. Again theres not a lot of clearance between the bracket and the leading driving wheel.

The chassis so far.

Moving on the next stage is the footplate, seen here in its assembly jig.

Re: Brassmasters Duchess test build

That's all looking appropriately massive and rather wonderful.

There's a case for making this a R/C battery powered dead track model; just so many metal components in realistically close proximity to all the wheel tyres.Jim S-W wrote:... As can be seen clearance is kind of on the minimal side...

Re: Brassmasters Duchess test build

Footplate with mounting bolts and Splashers in place and tided up ready for separating from the jig.

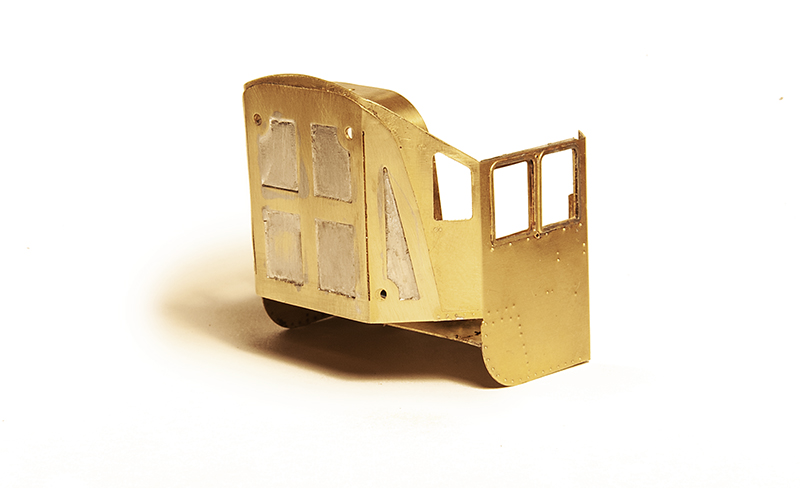

But before I can do that need to fit the cab, firebox, boiler and smoke box so that theres something to give it a degree of rigidity. This is the basic cab assembly.

And inside mounted to the footplate. The seats are posable!

The cab roof. This builds up on its own mini jig too.

Underside from the front end.

The main super structure comes in 3 parts cast in resin. The firebox and boiler. The smokebox saddle and the smoke box. There are 3 types. A round single chimney. The flattened top double chimney from the ex streamlined locos and a round double chimney as seen here.

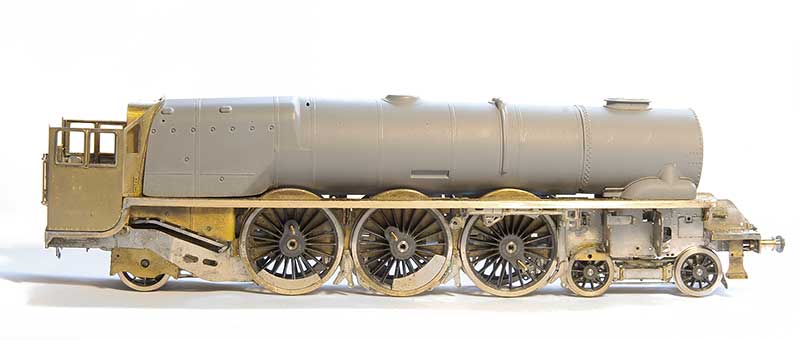

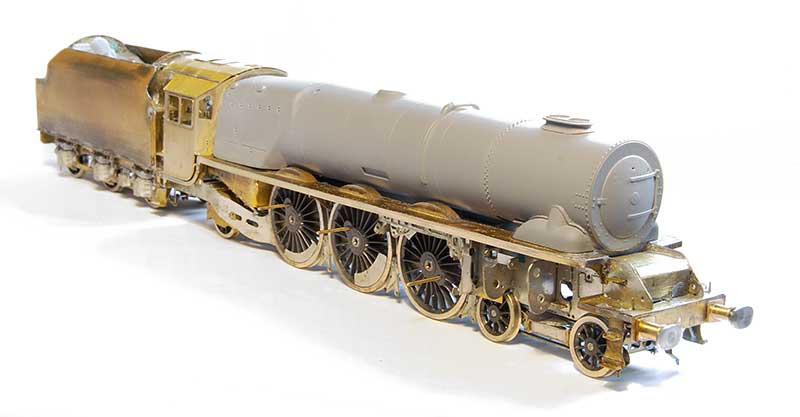

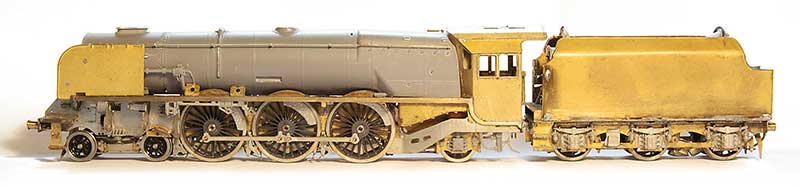

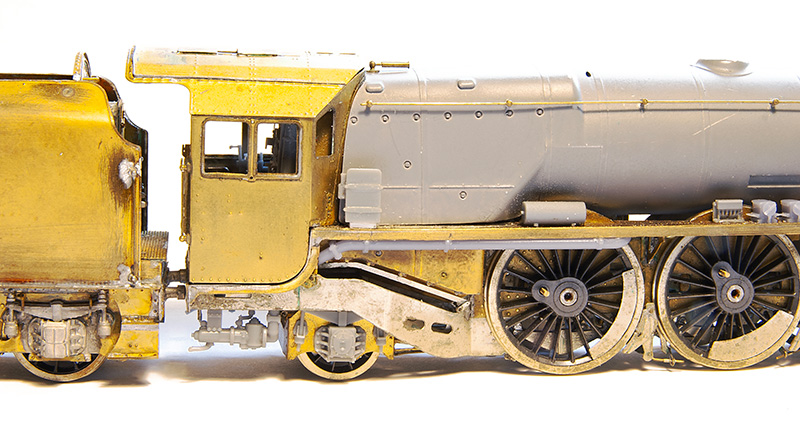

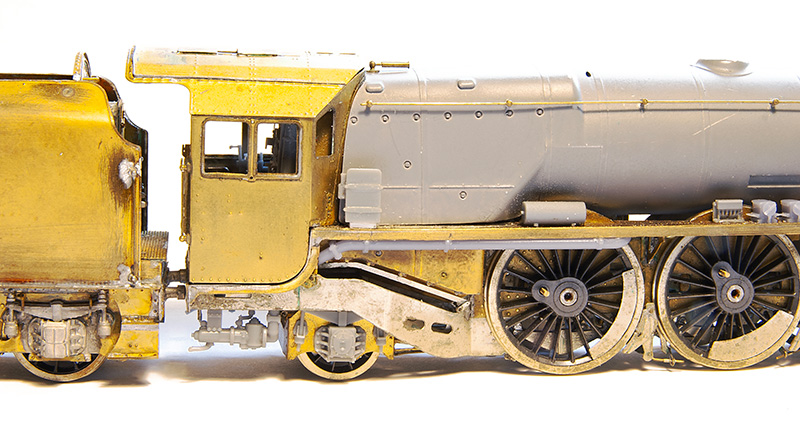

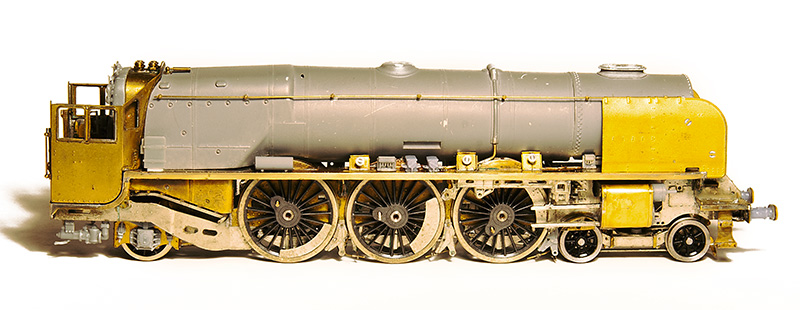

The body removed from the jig, tidied up and fitted to the chassis.

Finally - I couldn't resist!

Re: Brassmasters Duchess test build

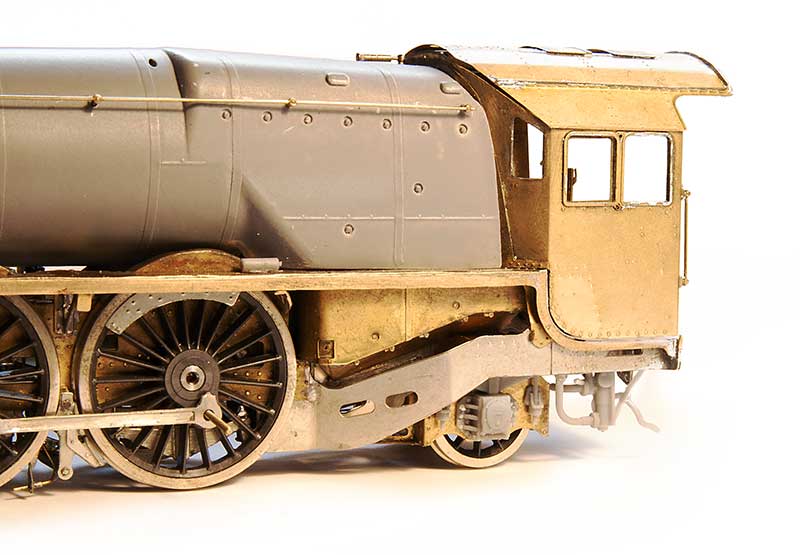

Just a little update this time - Been fitting some of the details to the body. Bogie wheels are temporary as I was doing a little testing (read that as shuffling it around on Brettell Road). I never realised how big these actually are. Right on the limit of the loading gauge!

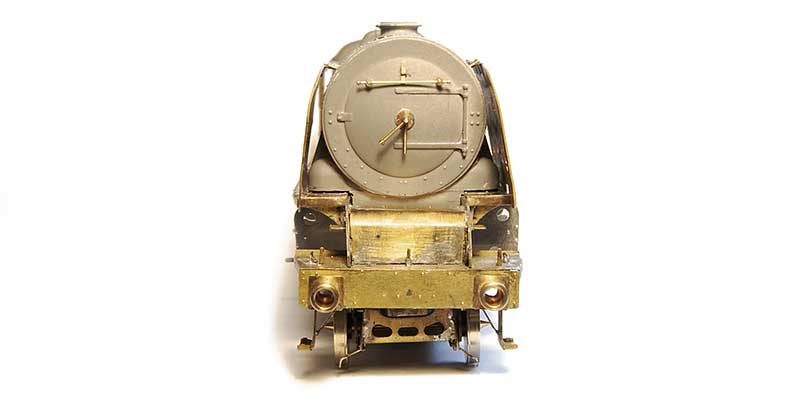

Head on view

Left hand side. - In addition to the body details Ive also added the sandpipes and springs. The latter in both senses as I've fitted the main functional springs to the model as well as the cosmetic ones behind the wheels

Re: Brassmasters Duchess test build

That is just wonderful workmanship Jim,

All so clean, some very tidy soldering.

A pleasure to see such a monster taking shape.

Geoff T

All so clean, some very tidy soldering.

A pleasure to see such a monster taking shape.

Geoff T

Remember ... I know nothing about railways.

http://www.newrailwaymodellers.co.uk/Fo ... 22&t=32187 and Another on http://www.newrailwaymodellers.co.uk/Fo ... &sk=t&sd=a

http://www.newrailwaymodellers.co.uk/Fo ... 22&t=32187 and Another on http://www.newrailwaymodellers.co.uk/Fo ... &sk=t&sd=a

Re: Brassmasters Duchess test build

That's coming along handsomely.

Those solid discs confer a North American appearance...Jim S-W wrote:... Bogie wheels are temporary ...

Re: Brassmasters Duchess test build

Yeah they do dont they?

Re: Brassmasters Duchess test build

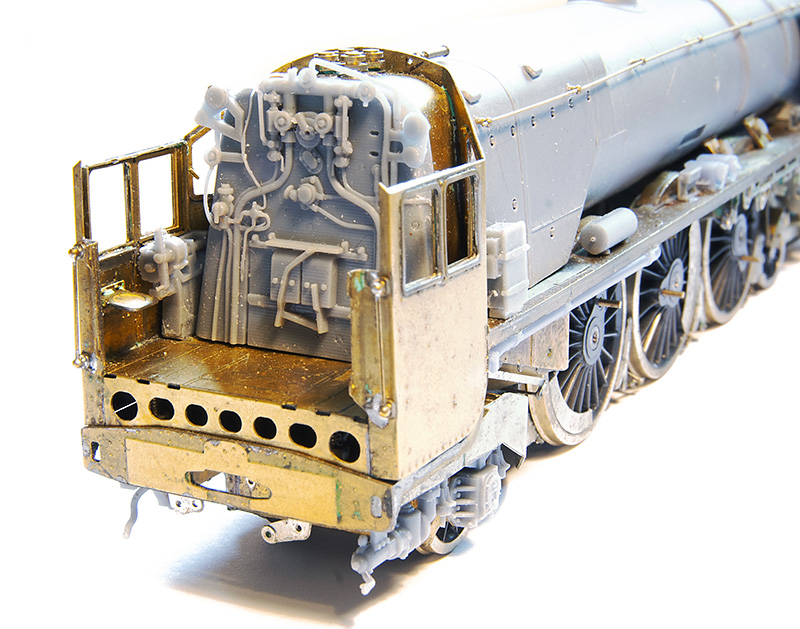

Progress on the Princess Coronation build continues with some test 3d prints for some of the details. These are only testing out ideas at this stage.

Above we see the bogie bearing pads and bracket, cylinder fronts, Ejector and brakes.

I admit that i had quite a wow! moment when I first saw the ejector. We are exploring the idea of 3d prints for the brake shoes as it allows you to position them closer to the wheels without risking a short. Where the front one squeezes in between the front driving wheel and the rear bogie wheel seems particularly advantageous.

Pony truck axlebox and springs along with some of the under cab pipework. One of the small AWS cylinders can be seen on the footplate

More AWS bits - this time on the firemans side. The roof is still a loose fit at this stage.

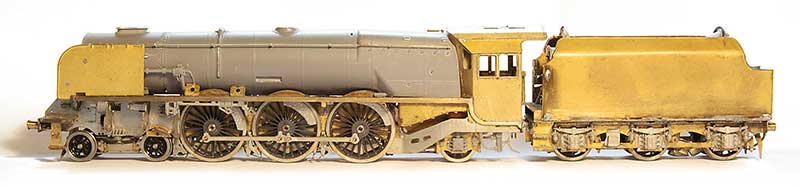

State of play so far.

Above we see the bogie bearing pads and bracket, cylinder fronts, Ejector and brakes.

I admit that i had quite a wow! moment when I first saw the ejector. We are exploring the idea of 3d prints for the brake shoes as it allows you to position them closer to the wheels without risking a short. Where the front one squeezes in between the front driving wheel and the rear bogie wheel seems particularly advantageous.

Pony truck axlebox and springs along with some of the under cab pipework. One of the small AWS cylinders can be seen on the footplate

More AWS bits - this time on the firemans side. The roof is still a loose fit at this stage.

State of play so far.

Re: Brassmasters Duchess test build

Looking better yet!. The clarity of the frame extension completely separate from the firebox casing is very striking. Having non-conductive static detail parts adjacent the wheel tyres has to be a good plan. While all metal equivalents are intrinsically strong and easy to reliably attach by soldering, the risk of intermittent shorts while the loco is in motion are only too well known.

Is it too early to ask what livery is intended for the finished model?

Is it too early to ask what livery is intended for the finished model?

Re: Brassmasters Duchess test build

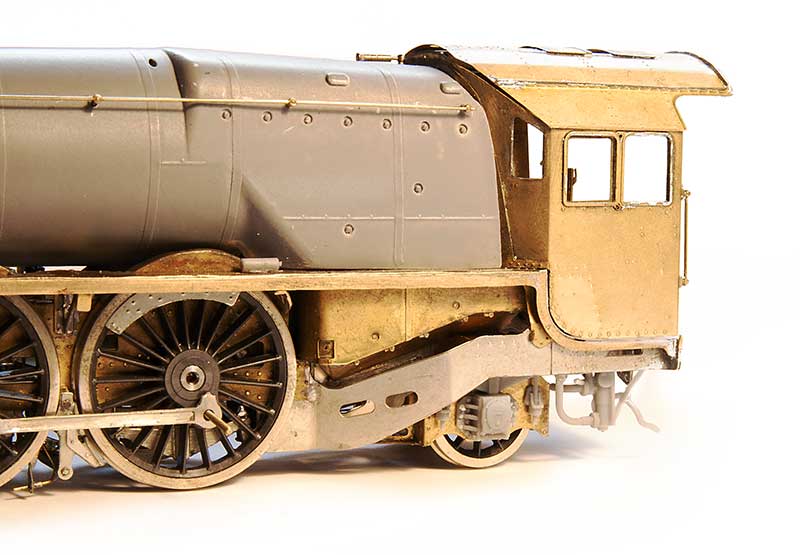

Its been 10 months since I did an update on the Duchess test build so its probably a little overdue.

The first bit of news, for those who don't follow the Brassmasters blog is that Geoff Hurley, the original kit designer, sadly passed away at the end of November 2023. He had been with Brassmasters for 20 years and in that time he designed their kits for the rebuilt Royal Scot, the LMS 4F and the Princess Royal as well their detailing kits for LMS locomotives. The Duchess was his last project before he became ill in 2022. I had a hope that I would get it finished and he would be able to see it but alas that wasn't to be.

This had meant that at lot of head scratching and trying to figure out where the project was has gone on since (not much of it by me I must add). So theres actually been an awful lot of work going on but it may not look like it.

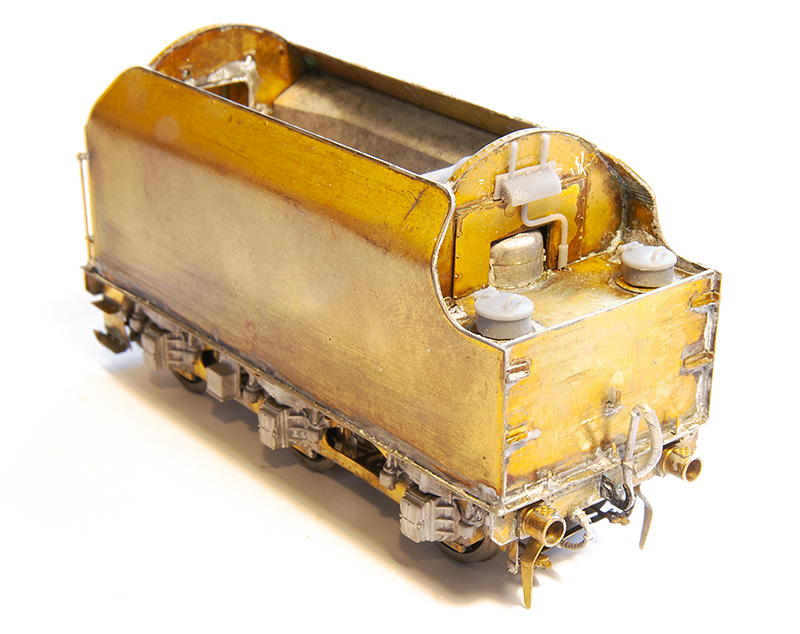

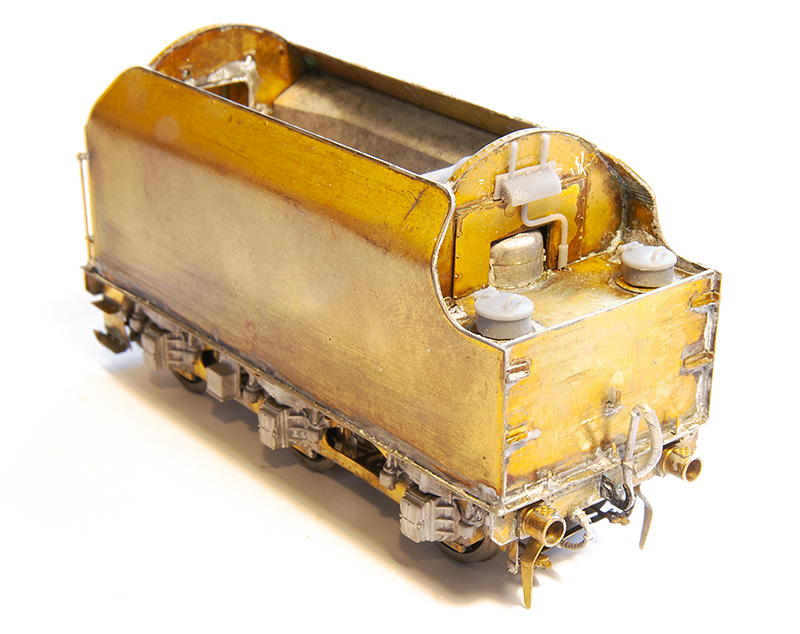

Some new bits for the tender. Originally the water tank hatches were white metal castings but these have been changed to 3d prints produced by David. The external part of the coal pusher is another 3d print.

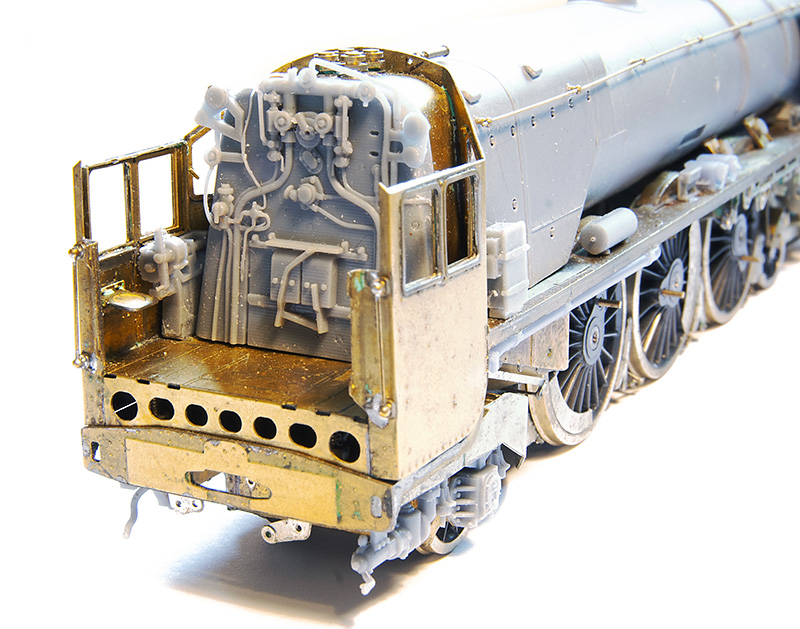

Moving foward the exhauster pipe and the under cab injectors. The latter have been through several versions mainly because of how we were going to mount them to the loco. This latest version seems to have cracked it but has necessitated a slight change to the etched artwork. The cab roof is a loose fit.

While on the subject of the cab heres some of the inner detail.

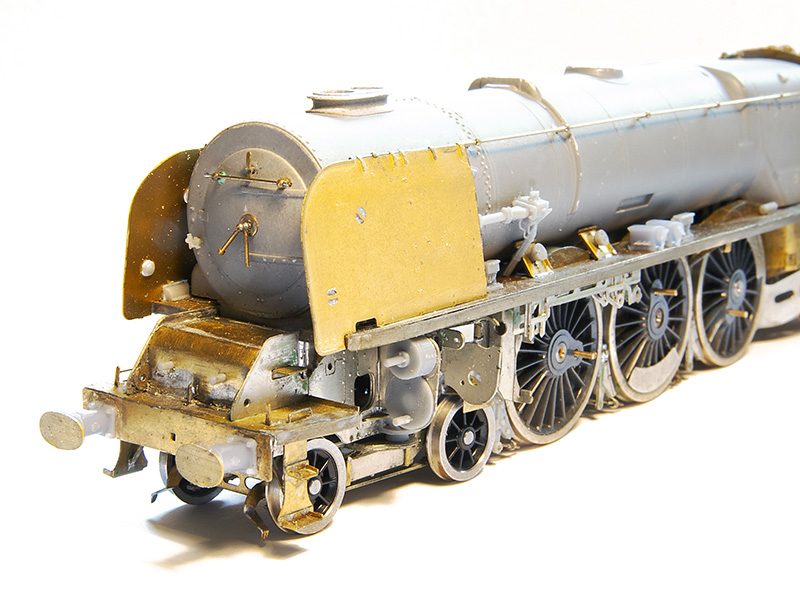

Some of the footplate details in place.

Moving on to the front, with health problems at Markits at the moment and being unable to supply stocks of their oval buffers we have looked at a 3d printed body with an etched head. This allows the buffer to be much more accurately detailed and while it does lose the springing the prototypes were not particularly know for coupling up to trains at this end.

The first bit of news, for those who don't follow the Brassmasters blog is that Geoff Hurley, the original kit designer, sadly passed away at the end of November 2023. He had been with Brassmasters for 20 years and in that time he designed their kits for the rebuilt Royal Scot, the LMS 4F and the Princess Royal as well their detailing kits for LMS locomotives. The Duchess was his last project before he became ill in 2022. I had a hope that I would get it finished and he would be able to see it but alas that wasn't to be.

This had meant that at lot of head scratching and trying to figure out where the project was has gone on since (not much of it by me I must add). So theres actually been an awful lot of work going on but it may not look like it.

Some new bits for the tender. Originally the water tank hatches were white metal castings but these have been changed to 3d prints produced by David. The external part of the coal pusher is another 3d print.

Moving foward the exhauster pipe and the under cab injectors. The latter have been through several versions mainly because of how we were going to mount them to the loco. This latest version seems to have cracked it but has necessitated a slight change to the etched artwork. The cab roof is a loose fit.

While on the subject of the cab heres some of the inner detail.

Some of the footplate details in place.

Moving on to the front, with health problems at Markits at the moment and being unable to supply stocks of their oval buffers we have looked at a 3d printed body with an etched head. This allows the buffer to be much more accurately detailed and while it does lose the springing the prototypes were not particularly know for coupling up to trains at this end.

Re: Brassmasters Duchess test build

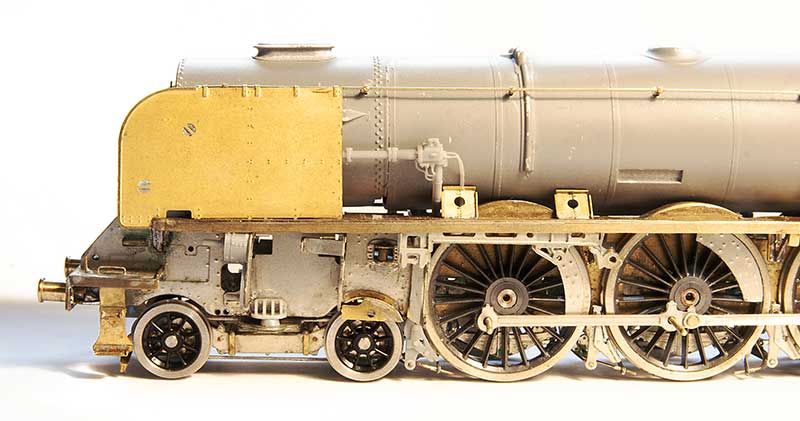

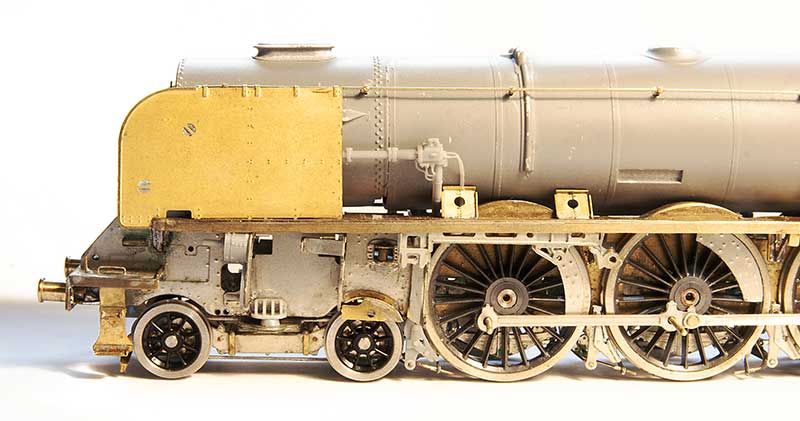

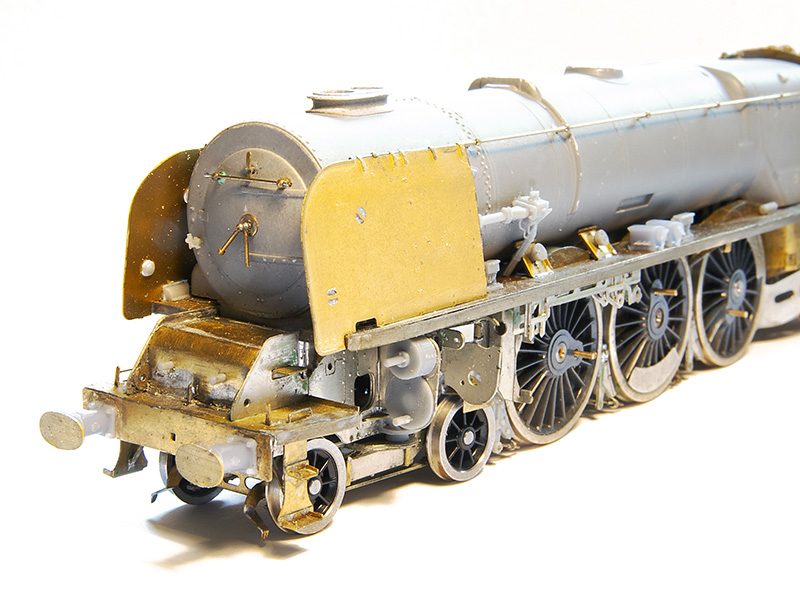

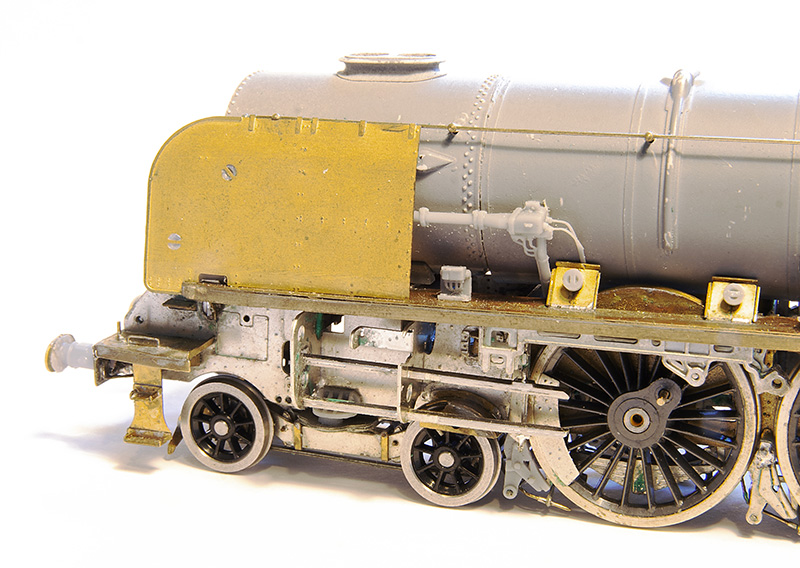

Some progress to report on the Duchess test build.

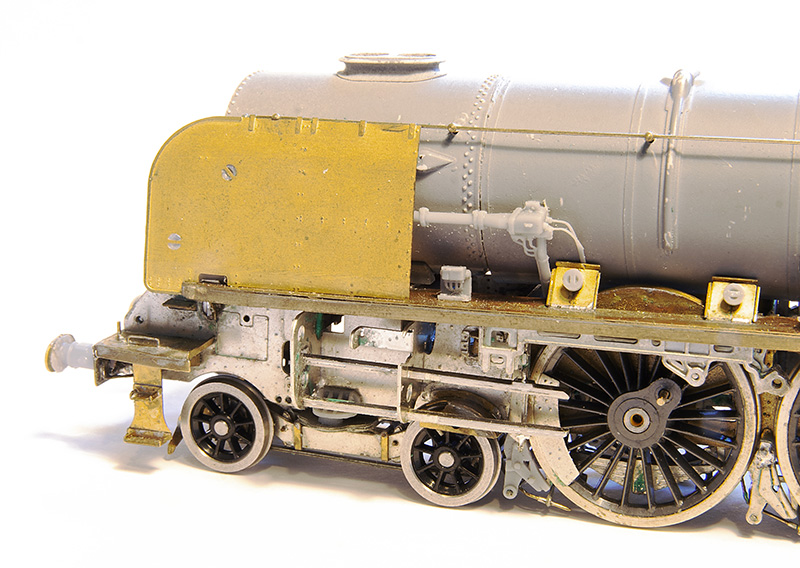

The original design that Geoff did for the cylinders was the same as the 7mm scale Finney kit. That uses cast slide bars soldered to the rear edge of the cylinder frame. In 4mm scale that wasn't going to work so David has redesigned this area to use a layered etch that goes through the rear face and solders to the front. This will be much stronger.

The cylinders viewed from above with the wrappers in place. Just behind the cylinders are the Valve rocking arms which as they need to be removable are held in place with a small screw.

Theres a lot of piping on the footplate of a Duchess!

The footplate is pretty much complete now.

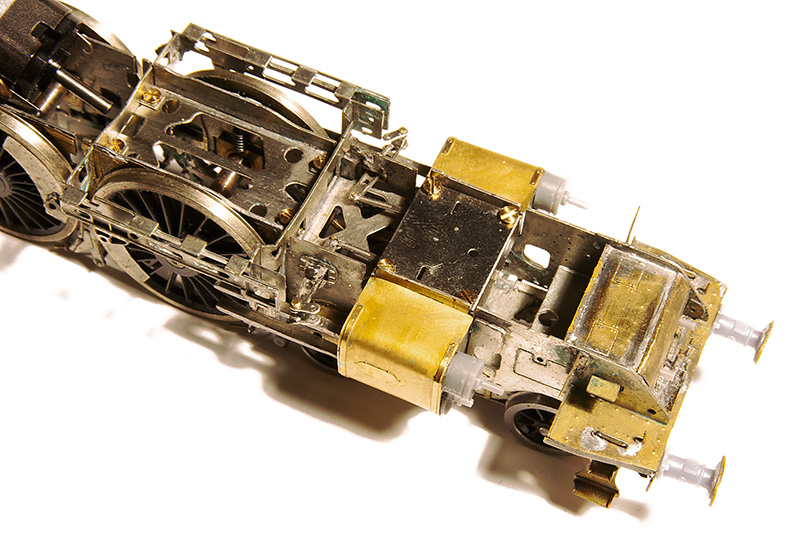

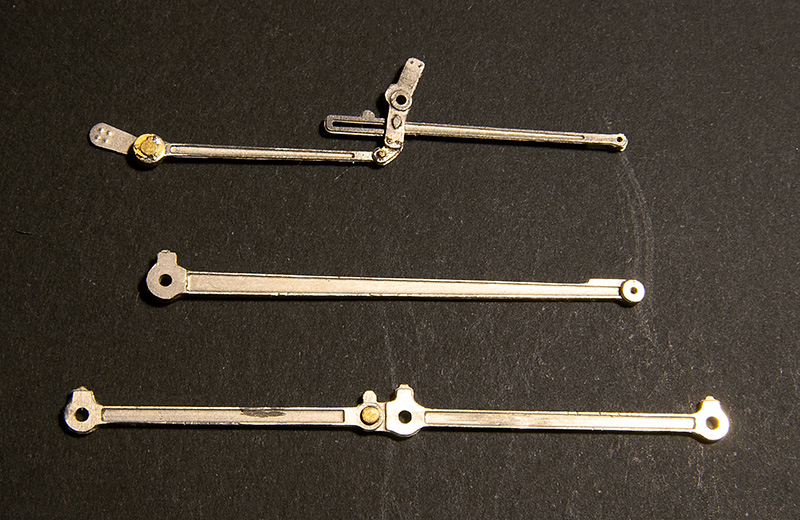

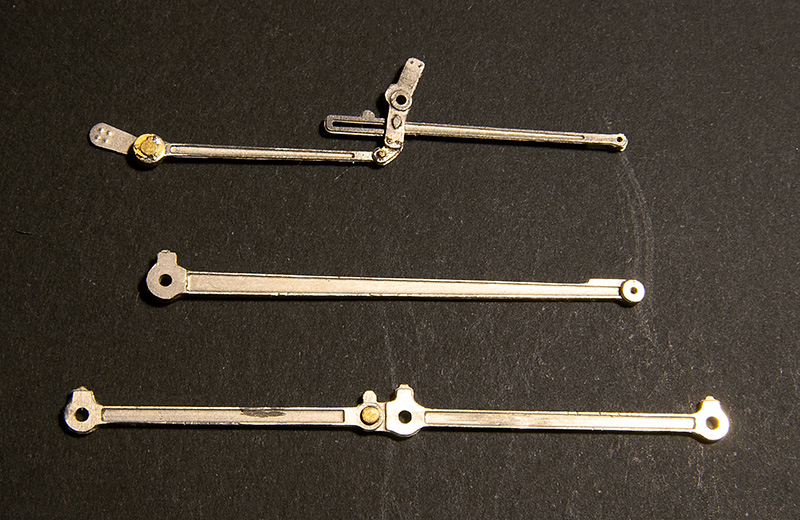

Made a start on the valve gear

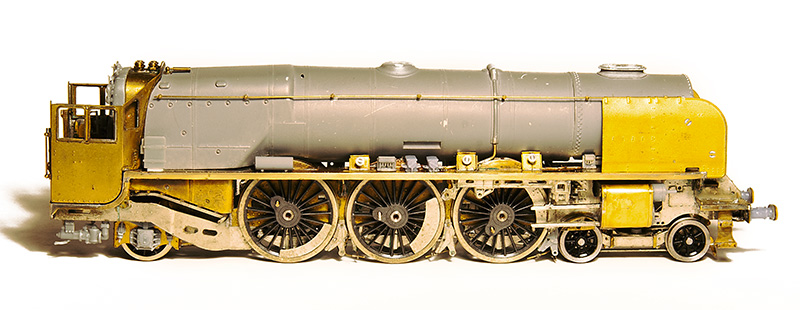

Progress so far.

The original design that Geoff did for the cylinders was the same as the 7mm scale Finney kit. That uses cast slide bars soldered to the rear edge of the cylinder frame. In 4mm scale that wasn't going to work so David has redesigned this area to use a layered etch that goes through the rear face and solders to the front. This will be much stronger.

The cylinders viewed from above with the wrappers in place. Just behind the cylinders are the Valve rocking arms which as they need to be removable are held in place with a small screw.

Theres a lot of piping on the footplate of a Duchess!

The footplate is pretty much complete now.

Made a start on the valve gear

Progress so far.

Re: Brassmasters Duchess test build

It is interesting seeing the assembly before it is all fully dressed and painted, as this emphasises how much skill was required to design a maximum power locomotive of sufficient power output for its intended duties, while staying within the boundaries of the running lines loading gauge, and capable of negotiating the restricted radii of the track in many major stations and loco yards. Great looking build, thanks for taking the time to post.