how to make a 'pickup' wagon

-

retiredoperator

- Posts: 143

- Joined: Sun Feb 15, 2015 8:25 am

Re: how to make a 'pickup' wagon

Hi Bufferstop I always value your opinion . I have been considering converting the following Locos to DCC, but being out of the model railway hobby for so long, I have lost some of my skills and become a bit clumsy. I have just ran Locos ( one at a time ) on an Inglenook puzzle

All three were coupled to a Queen Mary brakevan weighing in at 5ounces (146 g). And considering my poor track laying? performed okay. These Locos are ex Dapol 11232, 51240 &

16023. Of course I don't want to convert my QM Brake to a "Pick Up"? Or whatever it's called.

But any sensible suggestions on which wagon and a how to, would be appreciated .

Happy modelling Kev

All three were coupled to a Queen Mary brakevan weighing in at 5ounces (146 g). And considering my poor track laying? performed okay. These Locos are ex Dapol 11232, 51240 &

16023. Of course I don't want to convert my QM Brake to a "Pick Up"? Or whatever it's called.

But any sensible suggestions on which wagon and a how to, would be appreciated .

Happy modelling Kev

- Bufferstop

- Posts: 13819

- Joined: Thu Mar 11, 2010 12:06 pm

- Location: Bottom end of N. Warks line

Re: how to make a 'pickup' wagon

How good are you with a soldering iron, particularly in close proximity to plastic? other than using the coiled spring around the axles you have to fabricate some wipers, mount them under the chassis to bear on wheel rim, back, or the axles. If you choose axles you need to destroy the insulation at one end of each axle. (using real silver coloid paint). The other method uses coiled wire (like a spring) which sits on the axle, remove one wheel of each axle to fit it, put wheel back, reset gauge, destroy insulation.

Then you need two fine wires soldered to pick ups and threaded into loco body and soldered to the wires from the loco's own pickups.

This is where you start lifting points and relaying them so that the loco doesn't stall. I think the motto is "if you don't like the solution remove the problem". My trackwork isn't the worlds best but just by making sure the points are flat and then keeping the rail tops clean the pug doesn't stall.

Then you need two fine wires soldered to pick ups and threaded into loco body and soldered to the wires from the loco's own pickups.

This is where you start lifting points and relaying them so that the loco doesn't stall. I think the motto is "if you don't like the solution remove the problem". My trackwork isn't the worlds best but just by making sure the points are flat and then keeping the rail tops clean the pug doesn't stall.

Growing old, can't avoid it. Growing up, forget it!

My Layout, My Workbench Blog and My Opinions

My Layout, My Workbench Blog and My Opinions

-

retiredoperator

- Posts: 143

- Joined: Sun Feb 15, 2015 8:25 am

Re: how to make a 'pickup' wagon

Hi Bufferstop When i mentioned my track laying, the only thing wrong with it is that I glue it straight to the baseboard . No cork or any other underlay. I did a few years ago fit a grain of wheat bulb into a brakevan with a direct contact to the rails ( a bit of a bodge?)

I have read that Eileen's emporium carry phosphor bronze tor pick ups, any comment?

But it is the wire between the Loco and the wagon being fragile and liable to breakage?

Happy modelling Kev

I have read that Eileen's emporium carry phosphor bronze tor pick ups, any comment?

But it is the wire between the Loco and the wagon being fragile and liable to breakage?

Happy modelling Kev

- Bufferstop

- Posts: 13819

- Joined: Thu Mar 11, 2010 12:06 pm

- Location: Bottom end of N. Warks line

Re: how to make a 'pickup' wagon

Lack of underlay isn't a problem, but put a straight edge across the top of your points, many left to their own devices bulge up slightly at the frog, just the wrong place. It's a manufacturing problem that Peco have never bothered to correct. Probably because we don't complain enough about it. Seems to come on during the first year or so after manufacture.

Growing old, can't avoid it. Growing up, forget it!

My Layout, My Workbench Blog and My Opinions

My Layout, My Workbench Blog and My Opinions

-

retiredoperator

- Posts: 143

- Joined: Sun Feb 15, 2015 8:25 am

Re: how to make a 'pickup' wagon

Hi Bufferstop Thank you for your reply. After laying thr points and using them for a twelve month? Then it is too late. Now if I could make my own? I then I would because them who can are able to have the trackwork to suit their plans and not make do, with what is available . Happy modelling. Kev

- Bufferstop

- Posts: 13819

- Joined: Thu Mar 11, 2010 12:06 pm

- Location: Bottom end of N. Warks line

Re: how to make a 'pickup' wagon

I decided on, Sticking down points with Copydex not PVA, and pinning close to the frog straight after laying. A technician from BIP who I asked about the problem thought it was some kind of cold flow due to the stresses induced by the four bits of rail surrounding the frog.

Growing old, can't avoid it. Growing up, forget it!

My Layout, My Workbench Blog and My Opinions

My Layout, My Workbench Blog and My Opinions

-

retiredoperator

- Posts: 143

- Joined: Sun Feb 15, 2015 8:25 am

Re: how to make a 'pickup' wagon

Hi Bufferstop. I laid a straight endge(back of a engineers squre) a long the Peco electrofrog

frog as you suggested and you are absolutely correct , but not only that the insulated rail joiners (IRJs) seem to create an uneven joint, leaving a “step” in the track. Which is a right

PITA as far as smooth running is concerned .Happy Modelling. Kev

frog as you suggested and you are absolutely correct , but not only that the insulated rail joiners (IRJs) seem to create an uneven joint, leaving a “step” in the track. Which is a right

PITA as far as smooth running is concerned .Happy Modelling. Kev

Re: how to make a 'pickup' wagon

Peco's insulating rail joiner is a very poor piece indeed. I don't use it because it simply doesn't fit properly with the track it is intended for, the base of the joiner too thick to fit between rail bottom and the top of the moulded sleeper base, generating a bump in the rail every time. (Hopefully they will have given this some thought on their new bullhead rail points, and come up with something better?)

My method is 20 thou plasticard pieces between rail ends that need to be insulated when laying, and later fill the gap ahead of ballasting with a smear of milliput (terracotta colour) as insurance against movement leading to contact.

The reason for the induced upward bowing on points is mainly hysterisis of the formed curved rail pieces in my opinion. Unless fully stress relieved these curved rail pieces will slowly straighten very slightly after manufacture, and induce a bow in the complete assembly as a result. It can happen when hand building points on copperclad too, if assembly is performed quickly. Form the rail pieces ahead of time, and solder up a week later and the problem is not seen.

My method is 20 thou plasticard pieces between rail ends that need to be insulated when laying, and later fill the gap ahead of ballasting with a smear of milliput (terracotta colour) as insurance against movement leading to contact.

The reason for the induced upward bowing on points is mainly hysterisis of the formed curved rail pieces in my opinion. Unless fully stress relieved these curved rail pieces will slowly straighten very slightly after manufacture, and induce a bow in the complete assembly as a result. It can happen when hand building points on copperclad too, if assembly is performed quickly. Form the rail pieces ahead of time, and solder up a week later and the problem is not seen.

Re: how to make a 'pickup' wagon

I've not read this post before as I've never had, or feelt the need for a pick-up wagon.

But today, rather belatedly read it and don't particularly agree with Bufferstop on the

bowing of points being a manufacturing problem, although it is a phenomenon frequently

noted.

You have nickel silver metal rails embedded in plastic sleepers and framework. You could call

it an unfortunate mix of materials. Plastic has a coefficient of expansion and contraction

anything up to 4 times that of the metal used. Now when a point is trapped into position

with ballast and adjoining tracks where can that expansion go ? It usually manifests itself

by bowing upward as that's the point of least resistance. Hence the upward lift.

Pinning near the frog will restrain and reduce the effects, but those pressures of both

expansion when hot and contraction when cold are just simple facts of physics. Remember

those early flashing bulbs, using dissimilar metals that switched the bulb off when it got to

a certain temperature, than back on as they cooled ..... same principal. Metal sleeper would

solve one problem, but add more than worth thinking about.

Geoff T.

But today, rather belatedly read it and don't particularly agree with Bufferstop on the

bowing of points being a manufacturing problem, although it is a phenomenon frequently

noted.

You have nickel silver metal rails embedded in plastic sleepers and framework. You could call

it an unfortunate mix of materials. Plastic has a coefficient of expansion and contraction

anything up to 4 times that of the metal used. Now when a point is trapped into position

with ballast and adjoining tracks where can that expansion go ? It usually manifests itself

by bowing upward as that's the point of least resistance. Hence the upward lift.

Pinning near the frog will restrain and reduce the effects, but those pressures of both

expansion when hot and contraction when cold are just simple facts of physics. Remember

those early flashing bulbs, using dissimilar metals that switched the bulb off when it got to

a certain temperature, than back on as they cooled ..... same principal. Metal sleeper would

solve one problem, but add more than worth thinking about.

Geoff T.

Remember ... I know nothing about railways.

http://www.newrailwaymodellers.co.uk/Fo ... 22&t=32187 and Another on http://www.newrailwaymodellers.co.uk/Fo ... &sk=t&sd=a

http://www.newrailwaymodellers.co.uk/Fo ... 22&t=32187 and Another on http://www.newrailwaymodellers.co.uk/Fo ... &sk=t&sd=a

Re: how to make a 'pickup' wagon

The nicest, softest wire that I have found is from TCS or Zimo, attached to decoders. Offcuts may be long enough, but TCS, at least, sells rolls of wire.

Re: how to make a 'pickup' wagon

Regarding stalling on points. When I used to run my GWR 0-4-0 No. 101 I dont remember ever having an issue with it, yet many years layer the odd issue occurred. It took me a good while to put two and two together. The issues I had were when I later started to use Peco points. But why Peco? They were much nicer points and I was now on nickel silver where I used to run on Hornby steel points... All points had an insulated frog.

A thought came to me that the Hornby locos had Ben made with a wheelbase specifically to work through their pointwork where Peco pointwork was different. (I once read about the reason why Triang and then Hornby had designed their little locos with larger then scale wheels in diameter and the wheelbase being longer then needed, and it was due to the Ned to work with their pointwork.

A thought came to me that the Hornby locos had Ben made with a wheelbase specifically to work through their pointwork where Peco pointwork was different. (I once read about the reason why Triang and then Hornby had designed their little locos with larger then scale wheels in diameter and the wheelbase being longer then needed, and it was due to the Ned to work with their pointwork.

Modelling On A Budget ---》 https://www.newrailwaymodellers.co.uk/F ... 22&t=52212

-

retiredoperator

- Posts: 143

- Joined: Sun Feb 15, 2015 8:25 am

Re: how to make a 'pickup' wagon

Hi Bigmet. That looks an excellent idea, but it is a bit late for my current baseboard .

Would you please tell me, what is milliput used for? And can I purchase it in a builders merchant or a model shop without going “ online” and paying for P&P, without waiting for the postman? Happy modelling Kev

Would you please tell me, what is milliput used for? And can I purchase it in a builders merchant or a model shop without going “ online” and paying for P&P, without waiting for the postman? Happy modelling Kev

- Bufferstop

- Posts: 13819

- Joined: Thu Mar 11, 2010 12:06 pm

- Location: Bottom end of N. Warks line

Re: how to make a 'pickup' wagon

Hi retiredoperator - Milliput is a two part putty come filler. It's used by working equal amounts of the two parts until fully blended. It will then start to harden. You can make adjustments for around 30 minutes, after which it should be left overnight. Once hardened it can be sawn, filed, drilled and sanded. It's generally available craft shops and some hardware stores as well as through the model trade.

Growing old, can't avoid it. Growing up, forget it!

My Layout, My Workbench Blog and My Opinions

My Layout, My Workbench Blog and My Opinions

-

retiredoperator

- Posts: 143

- Joined: Sun Feb 15, 2015 8:25 am

Re: how to make a 'pickup' wagon

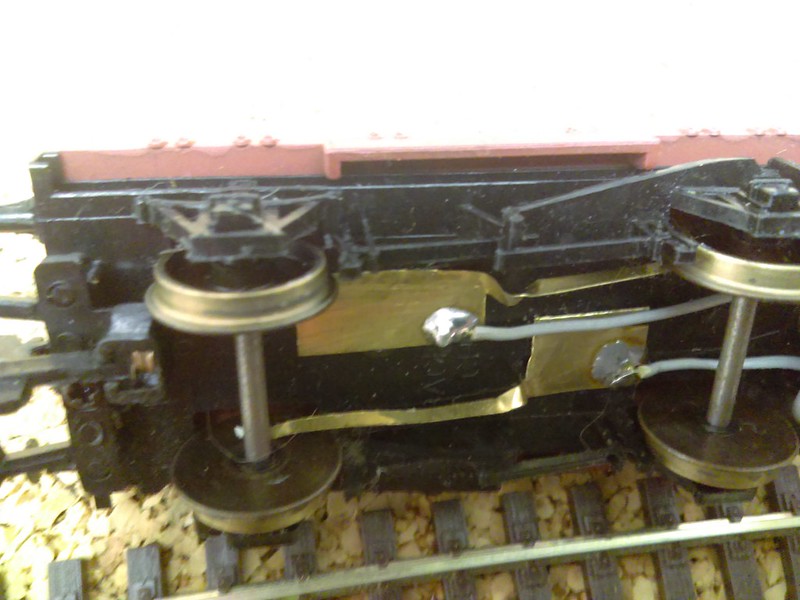

Hi D605 Eagle. Thank you for your photos, of the “extra pickup wagon”. Is that Brass or Phosphor Bronnze? And how is it for keeping contact with the wheels? Nearly fifty years ago I used an old lid off a jam jar that worked well, but things have moved on since. The choice of flexible wire is another concern, though TCS are a recommended supplier that I must contact

Happy modelling. Kev

Happy modelling. Kev